Project Gallery

A selection of the most impressive and recent jobs, each with a visual highlight and summary.

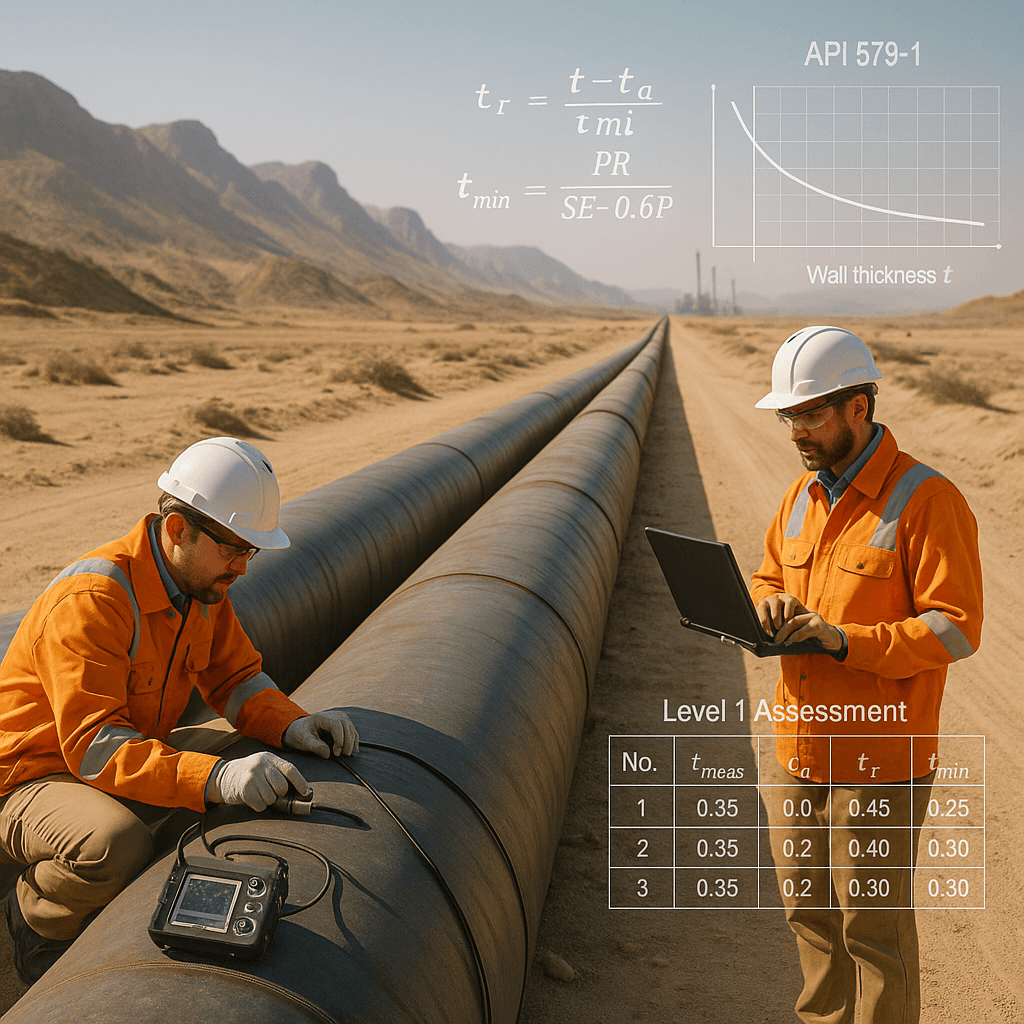

Pipeline Fitness-For-Service Analysis – ENI Iraq (50 KM Pipeline)

Performed Level 2 FFS evaluation for a 50-kilometer crude oil pipeline affected by wall thinning and corrosion. Calculations included remaining life estimation, required thickness, and safe MAWP per API 579.

Dented Pressure Vessel Assessment – DNV (Third-Party Audit)

Conducted dent evaluation and rerating of pressure vessels in line with ASME VIII and API 579. Developed fitness conclusions and repair recommendations for compliance and recertification.

Asset Integrity Gap Analysis – EGPC Refineries (APC, APRCO, ASORC)

Led multi-site audits for EGPC affiliates to assess gaps in asset integrity compliance. Provided full ISO 55001-based recommendations, policy framework, and organizational alignment roadmap.

Fired Boiler Integrity Study – Egypt (Standalone Plant)

Evaluated aging fired tube boiler for structural integrity and corrosion. Calculated safe operating limits, identified degradation zones, and prepared re-rating documentation.

Tank FFS Evaluations – AMAL, ZETCO, GEMSA

Inspected and analyzed multiple above-ground storage tanks. Included shell bulge analysis, bottom plate thickness evaluations, corrosion rate estimations, and remaining life predictions.

Air Coolers FFS Calculations – Egypt

Analyzed mechanical integrity of air coolers subject to vibration and fouling. Delivered safe operating recommendations and repair/replace decisions for critical shutdown avoidance.

Recalibration of 70+ Safety Valves – Egyptian LNG (Bureau Veritas Project)

Conducted recalibration, testing, and documentation of pressure relief valves during turnaround. Aligned all procedures with API 576 and plant-specific QA/QC plans.

Shutdown QA/QC Supervision – Shell Pearl GTL / Qatar Petroleum

Managed QA/QC activities during major shutdowns. Reviewed test packages, oversaw hydrotests, and validated mechanical completions of pressure systems.

Structural & Welding QA Management – DANIELI Italy @ EZZ Steel Plant

Implemented QA/QC control plans for heavy steel structures, welding, and inspection during steel plant construction in coordination with Italian design authorities.